Henan Sicheng Abrasives Tech Co., Ltd. was founded in 2010 as a technology-driven enterprise specializing in the production, research, development, and sales of a diverse range of abrasive materials, refractory materials, and foundry materials. Leveraging advanced manufacturing processes and a dedicated sales service team, we deliver high-quality products and services to numerous partners worldwide.

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting.

Brown fused alumina is produced by melting high-quality bauxite, iron filings, and anthracite in an electric arc furnace at high temperatures.

Black silicon carbide is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace.

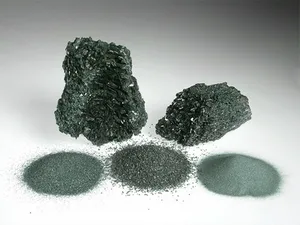

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace.

Tabular alumina is a pure sintered alumina, thoroughly calcined without the addition of any additives such as MgO or B2O3.

Zirconia fused alumina is produced by melting aluminum oxide and zirconium oxide in an electric arc furnace at temperatures above 2000°C.

Chromite foundry sand, with its main chemical component Cr2O3, boasts thermal stability, high thermal conductivity, and excellent resistance to alkali slag.

Ceramic foundry sand is made from high-quality alumina and vanadium clay, processed through electric fusion, granulation, and screening processes to produce spherical refractory particles.

Our company specializes in the production of various abrasives, refractory materials, and foundry materials. Our products serve a wide variety of industries worldwide, and we strive to understand the potential applications for our products across different sectors.

Customers often encounter challenges where the surfaces of their work pieces are contaminated with dyes, paints, rust, oxides, or other stubborn residues that are difficult to remove. These stains not only affect the aesthetics of the objects but may also compromise their performance and interfere with subsequent processing stages.