Surface finishing is a process that treats the surface of a work piece using compressed air to create a high-speed jet that propels abrasives (such as white fused alumina, brown fused alumina, garnet, glass beads, etc.) At high speed onto the work piece. This changes the surface's appearance or shape. The impact and cutting action of the abrasive on the work piece surface results in a certain level of cleanliness and varying roughness, enhancing the mechanical properties of the surface.

With 20 years of experience, Sicheng is a professional manufacturer and processor of sandblasting materials, producing about 10,000 tons per month.

Sicheng's casting materials are manufactured in strict accordance with international industry standards, equipped with in-house laboratories and professional testing equipment to ensure stringent quality control.

Our company offers a variety of materials for sandblasting, providing different solutions to meet various customer needs. Recommended products for sandblasting include: white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide, glass beads, zirconia alumina, and chrome alumina.

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting.

Brown fused alumina is produced by melting high-quality bauxite, iron filings, and anthracite in an electric arc furnace at high temperatures.

Zirconia fused alumina is produced by melting aluminum oxide and zirconium oxide in an electric arc furnace at temperatures above 2000°C.

Pink aluminum oxide or ruby aluminum oxide is made by aluminum oxide powder, which is electrically fused at high-temperature by adding appropriate amount of chromium oxide, etc.

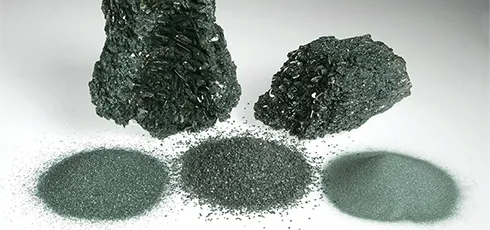

Black silicon carbide is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace.

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace.

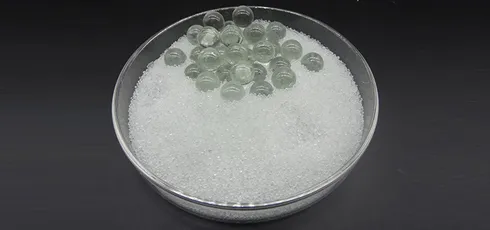

Glass beads, produced from crushed glass and flat glass materials, are processed into spherical shapes through high-temperature melting.

Coatings are widely used in various industries, including automotive, aerospace, infrastructure, pipelines, oil and gas, mining, and shipbuilding.

Abrasives are tools used for grinding, polishing, and buffing. Most abrasives are man-made, consisting of abrasives and a bonding agent (like grinding wheels).

Polishing compounds generally use finer abrasive micro-powders (such as white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide) as raw materials, which are further processed into polishing paste, polishing wax, and polishing liquid for convenient use in the polishing process.

Using synthetic abrasives (white fused alumina, chrome corundum, black silicon carbide, green silicon carbide) as raw materials, various ceramic products such as ceramic crucibles and ceramic membranes are made by adding different binders and processing them at high temperatures.