Abrasives are tools used for grinding, polishing, and buffing. Most abrasives are man-made, consisting of abrasives and a bonding agent (like grinding wheels). The applications for abrasives are vast; they are widely used not only in mechanical manufacturing and other metal processing industries but also in processing non-metal materials like grain, paper, ceramics, glass, stone, plastic, rubber, and wood. Therefore, high-quality and diverse abrasive products are required.

The production and manufacture of abrasives require a variety of products and models, and we can meet the diverse needs of our customers.

Our company has a professional technical team and after-sales service team, providing customers with technical support and solutions, including tool selection and usage guidance, helping customers improve production efficiency and product quality.

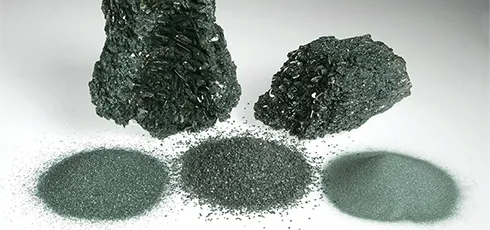

The commonly used abrasives for manufacturing tools include white fused alumina, brown fused alumina, zirconia fused alumina, chrome corundum, black silicon carbide, green silicon carbide, and boron carbide. Due to the different work pieces and desired effects, customers require different products and models.

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting.

Brown fused alumina is produced by melting high-quality bauxite, iron filings, and anthracite in an electric arc furnace at high temperatures.

Zirconia fused alumina is produced by melting aluminum oxide and zirconium oxide in an electric arc furnace at temperatures above 2000°C.

Pink aluminum oxide or ruby aluminum oxide is made by aluminum oxide powder, which is electrically fused at high-temperature by adding appropriate amount of chromium oxide, etc.

Black silicon carbide is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace.

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace.

Boron carbide is produced through high-temperature smelting of boracic acid and carbonaceous materials in electric furnaces.

Polishing compounds generally use finer abrasive micro-powders (such as white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide) as raw materials, which are further processed into polishing paste, polishing wax, and polishing liquid for convenient use in the polishing process.

Using synthetic abrasives (white fused alumina, chrome corundum, black silicon carbide, green silicon carbide) as raw materials, various ceramic products such as ceramic crucibles and ceramic membranes are made by adding different binders and processing them at high temperatures.

Metallurgy refers to the process and techniques of extracting metals or metal compounds from minerals and processing them into metal materials with specific properties through various methods.

Investment casting involves melting solid metal into a liquid state and pouring it into a mold to form a specific shape, which then solidifies.