Henan Sicheng Abrasives Tech Co., Ltd. was founded in 2010 as a technology-driven enterprise specializing in the production, research, development, and sales of a diverse range of abrasive materials, refractory materials, and foundry materials. Leveraging advanced manufacturing processes and a dedicated sales service team, we deliver high-quality products and services to numerous partners worldwide.

Henan Sicheng Abrasives Tech Co., Ltd.

Sicheng Abrasives

A one-stop shop for your abrasive grain and fused mineral materials

White Fused Alumina, Brown Fused Alumina, Fused Zirconia Alumina, Pink Fused Alumina, Black Silicon Carbide …

1903, Yaxing Times Square, Changjiang Road and Songshan Road Intersection, Erqi Area, Zhengzhou City, Henan Province, China

Email: sichengym1903@gmail.com

Bubble alumina is a new type of high-temperature insulation material, consisting of a-Al2O3 microcrystals.

Boron carbide is produced through high-temperature smelting of boracic acid and carbonaceous materials in electric furnaces. It boasts a theoretical density of 2.52g/cm3, a melting point of 2450°C, and a micro hardness of 4950kgf/mm2. Its exceptional hardness, second only to diamond and cubic boron nitride, coupled with its high temperature resistance, acid-alkali corrosion resistance, high strength, chemical stability, and lightweight, make it an ideal material across various industries.

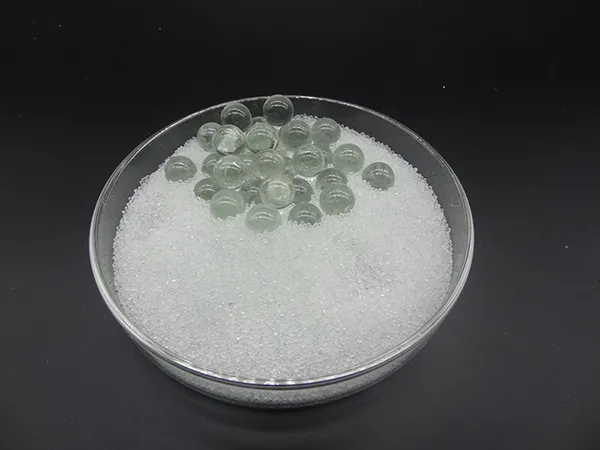

Glass beads, produced from crushed glass and flat glass materials, are processed into spherical shapes through high-temperature melting.

Ceramic foundry sand is made from high-quality alumina and vanadium clay, processed through electric fusion, granulation, and screening processes to produce spherical refractory particles.

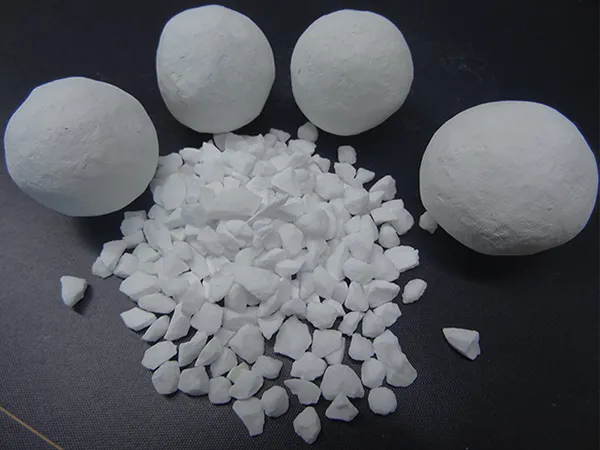

Tabular alumina is a pure sintered alumina, thoroughly calcined without the addition of any additives such as MgO or B2O3. It boasts a coarse, well-developed α-Al2O3 crystal structure, with an Al2O3 content exceeding 99%.

Chromite foundry sand, with its main chemical component Cr2O3, boasts thermal stability, high thermal conductivity, and excellent resistance to alkali slag. It prevents metal penetration and sand sticking, making it ideal for various stainless steel, alloy steel, and carbon steel core-making applications.

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace. It appears as green crystals, is brittle and sharp, and has certain thermal and electrical conductivity.

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting. It features high purity, excellent self-sharpening properties, resistance to acid and alkali corrosion, high-temperature stability, and stable thermal performance. It is slightly harder than brown fused alumina but less tough. With strong grinding capabilities, low heat generation, and high efficiency, it is suitable for making abrasive tools used for grinding high-carbon steel, high-speed steel, and stainless steel.