Metallurgy refers to the process and techniques of extracting metals or metal compounds from minerals and processing them into metal materials with specific properties through various methods.

The metallurgy industry requires a large number of refractory materials and abrasives for the processes of iron and steel making. Our products can meet the industry's needs for high-temperature resistance, wear resistance, polishing, and surface treatment, providing reliable solutions to support the development and advancement of the metallurgy industry.

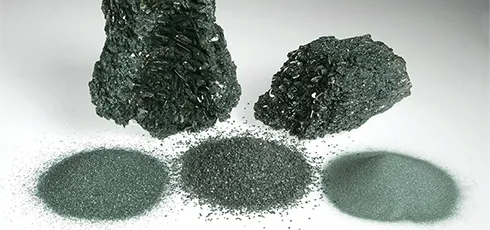

Black silicon carbide is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace.

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace.

Investment casting involves melting solid metal into a liquid state and pouring it into a mold to form a specific shape, which then solidifies.

Refractory materials are inorganic, non-metallic materials that can withstand high temperatures and meet usage requirements in high-temperature environments.

Surface finishing is a process that treats the surface of a work piece using compressed air to create a high-speed jet that propels abrasives (such as white fused alumina, brown fused alumina, garnet, glass beads, etc.) At high speed onto the work piece.

Coatings are widely used in various industries, including automotive, aerospace, infrastructure, pipelines, oil and gas, mining, and shipbuilding.