Coatings are widely used in various industries, including automotive, aerospace, infrastructure, pipelines, oil and gas, mining, and shipbuilding. Our products can serve as additives in coatings to enhance their performance. Metal oxides and fused mineral powders and granules can improve the chemical resistance and mechanical properties of coatings, while also enhancing optical characteristics and anti-slip properties. For example, adding white fused alumina or green silicon carbide to floor coatings can increase their wear resistance and anti-slip properties, significantly extending the coating's lifespan and providing some level of fire resistance.

Our factory offers commonly used models of white fused alumina and green silicon carbide for coating additives, with a complete range of sizes, the finest reaching up to 10000#. We can provide different products and models according to various customer needs.

Our products meet the standards and specifications of the coatings industry, such as durability, corrosion resistance, and gloss requirements. This ensures that our products can meet the needs of different customers and projects.

White Fused Alumina and Green Silicon Carbide for coatings (recommended sizes: 180#, 220#, 240#, 280#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500#, 2000#, 2500#, 3000#, 4000#, 5000#, 6000#, 8000#, 10000#)

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting.

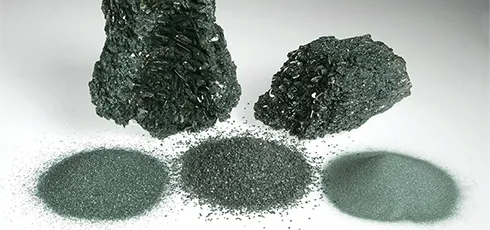

Green silicon carbide is made from petroleum coke and high-quality silica, with salt added as an additive, and refined in a high-temperature resistance furnace.

Abrasives are tools used for grinding, polishing, and buffing. Most abrasives are man-made, consisting of abrasives and a bonding agent (like grinding wheels).

Polishing compounds generally use finer abrasive micro-powders (such as white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide) as raw materials, which are further processed into polishing paste, polishing wax, and polishing liquid for convenient use in the polishing process.

Using synthetic abrasives (white fused alumina, chrome corundum, black silicon carbide, green silicon carbide) as raw materials, various ceramic products such as ceramic crucibles and ceramic membranes are made by adding different binders and processing them at high temperatures.

Metallurgy refers to the process and techniques of extracting metals or metal compounds from minerals and processing them into metal materials with specific properties through various methods.